Manufacturers

are Heroes

We help you save time and improve efficiency and quality

Let's work Let's talkThe information comes from your existing machines and systems

We help you save time and improve efficiency and quality

Let's work Let's talkThe information comes from your existing machines and systems

"... I especially appreciate Tark Tööstus' focus on understanding and finding opportunities to better utilize our company's resources for business growth, meaning their work doesn't include 'nice to have' developments but rather solutions that bring real value to the company." Marek Hirs, Rait AS Production Manager

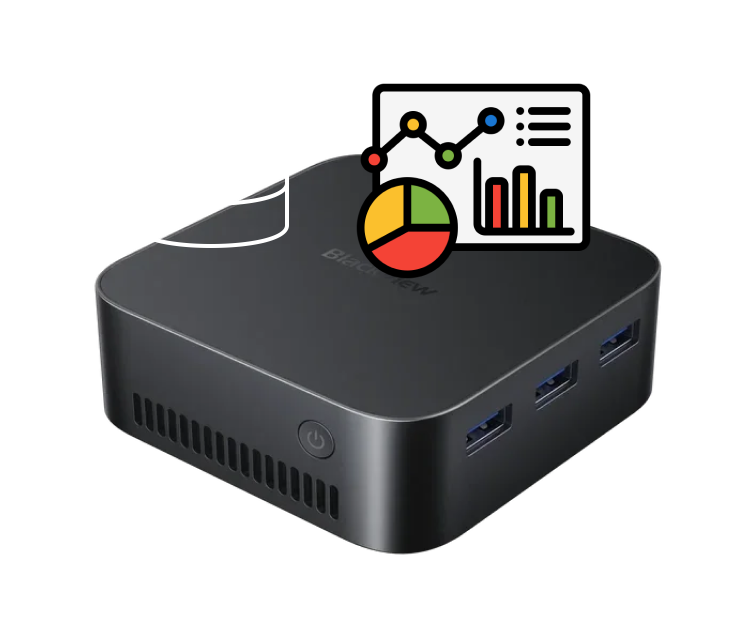

Digitalization: using technology to improve speed, quality, or influence costs.

As a whole, it is a long and complex process, but we can start it quickly and simply.

All activities should move the company towards value.

All systems should support this, fitting with the people and the process.

To create value, we need to understand you as well as possible.

What is going well, what can be improved, and what are the company's

goals?

Free

2-5 day workshop (depending on company size and number of processes).

We describe the theory, provide examples, and then analyze your company

specifically.

Price: 1200 EUR/day

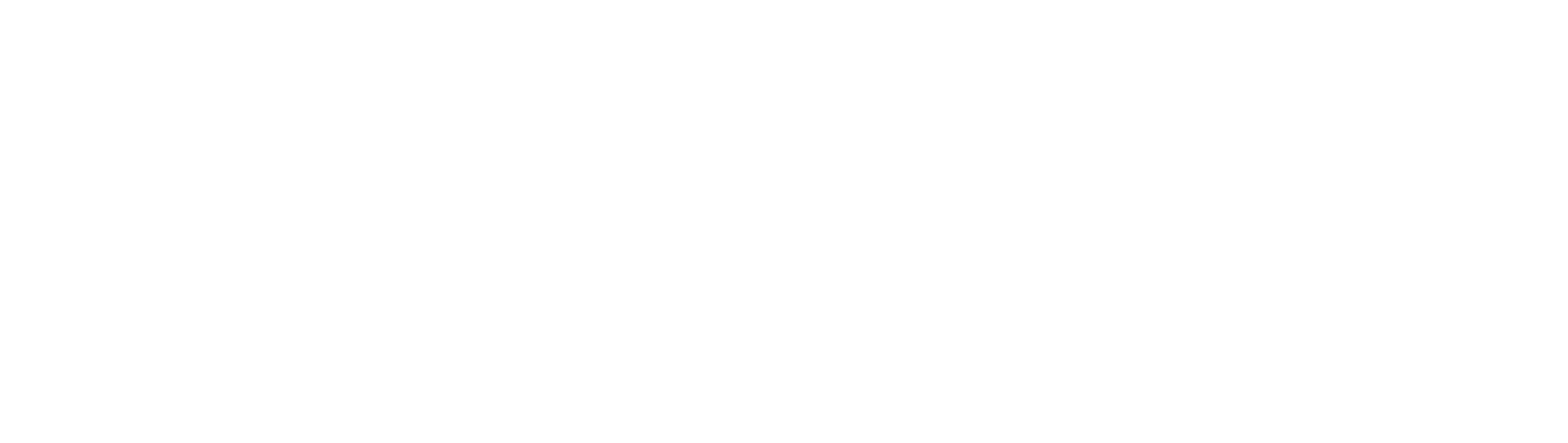

Business Architecture Request a QuoteWe use EIS support to create a clear picture of the current situation (processes, systems, people, skills).

We identify bottlenecks and establish a roadmap—specific actions needed to reach your

goals.

Price: 10-25 thousand EUR, with up to 50% covered by EIS

Without integrating machines and systems, there is no real overview.

If activities are carried out using Excel or written on paper,

then planning and troubleshooting is time-consuming and the risk of errors is high.

Kratt is a simplified SCADA system.

1 Kratt can read from 1 machine:

After that, Kratt will need a companion.

1 Kratt costs 125 EUR/month

Immediately after installation, the following are available (free):

Effective work happens when people/robots, tools, and materials meet.

Smart MES is a simplified MES and APS: plan, manage, monitor.

If there is a machine error, the person explains why.

Based on this, we build custom machine learning and automation for you.

MES starts at 300 EUR/month.

Price depends on the number of users.

Creating visibility is quick, and the investment pays off within hours.

Comprehensive digitalization is unique for every company: your people, processes, and systems.

Example: "Production speed" or "Electricity usage" is valuable information.

By analyzing this across products, machines, and operator metrics, we can make precise decisions.

The goal of Industry 4.0 is to connect data.

Price: ERP and MES integration 1000 EUR (one-time)

We use Beckhoff hardware.

Open ecosystem, easy access to data.

Price: Custom solution

We analyze efficiency, energy consumption, quality, and financial value based on 1 week or 1 month's data.

Price: Custom solution

Firstly people, then processes, and finally solutions

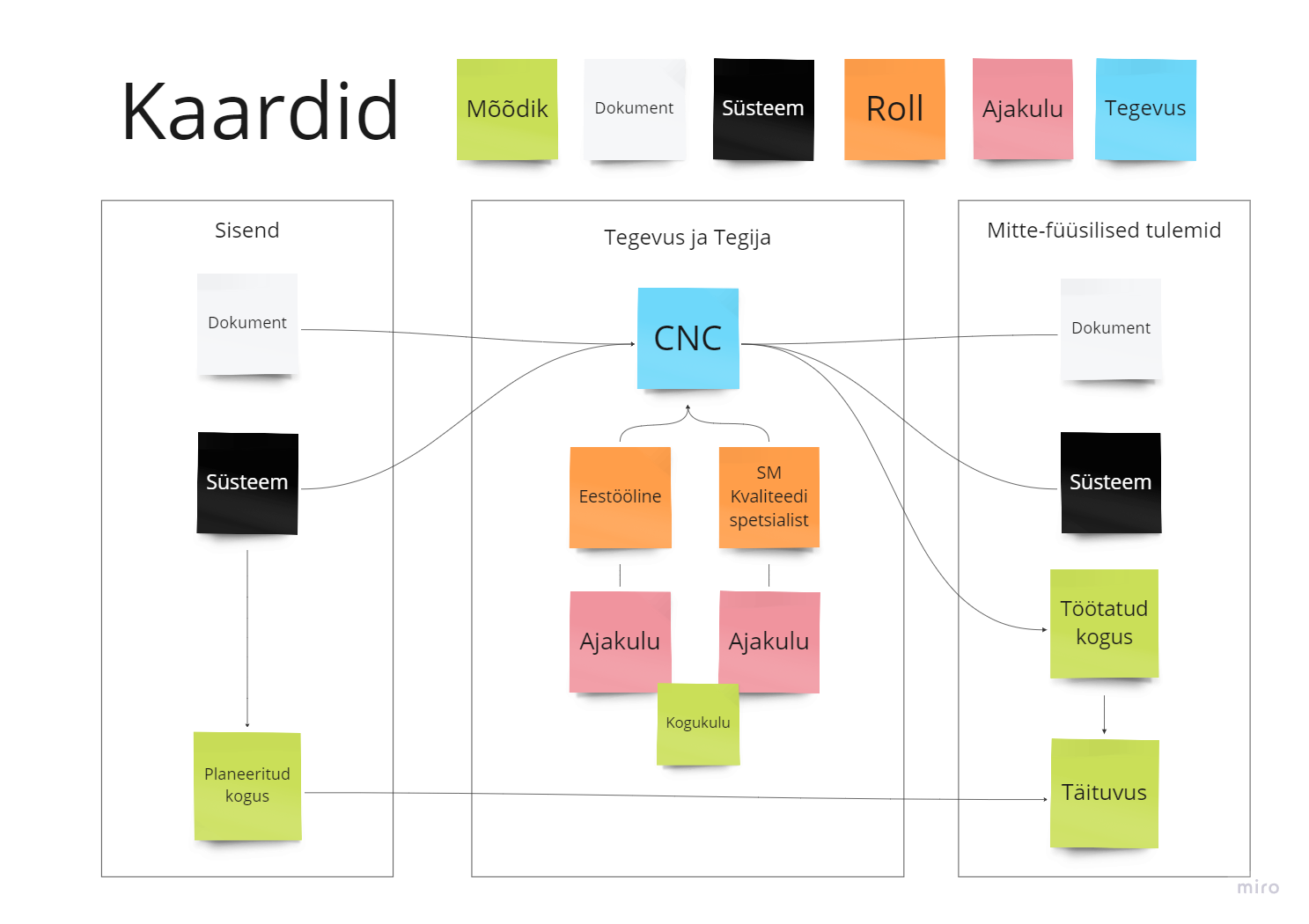

- people, machines, processes

- products, orders, materials, actions, etc.

to automatically collect data in order to

improve accuracy, speed, and reduce costs

More specifically:

All activities should move the company towards value.

All systems should support business and fit with people and processes.

Information must flow top-to-bottom and left-to-right, reliably.

1. Business architecture - how to support the business with modern

solutions.

Compatible with Enterprise Estonia Digitalization grants.

2. Data and visibility - how to collect data from machines, people, and

processes and transfer it to connected systems (e.g., ERP).

The lack of data and manual

work are the biggest obstacles to digitalization.

All systems must support the business goals

Sensor data shows machine operation in real-time.

In case of defects, data from different machines and systems can be checked to quickly find the errors.

Automatic data collection allows predicting equipment failures, reducing the risk of downtime and maintenance costs.

Reports require a lot of manual work. With data available, reports can be generated automatically.

Additionally, some audits require data completeness and history, which cannot be ensured manually.

Orders, BOMs, material availability, delivery info, employee schedules, and production line speeds are all in one place.

A new order reaches the project, engineering, and procurement departments. After confirmation, the information goes to production.

Each dataset should have one place for adding and modifying, e.g., customer data is in the CRM, and

the material list is in the ERP.

Other systems must use this data, not re-enter it.

If the BOM (recipe) of products is available, we know how much material has been consumed for each finished product.

Six Sigma describes process variability - how much reality differs from the model and past

production.

If there is a process model for production, sensor data, and operator notes, the production

efficiency can be automatically assessed.

Use machine learning to predict maintenance needs and avoid unexpected equipment failures, reducing work interruptions.

Machine learning allows precise forecasting of seasonal demand, optimizing production and inventory management.

If the outbound warehouse is full, production speed is automatically reduced to avoid overproduction.

System settings automatically change according to the order to ensure production efficiency.

Equipment is automatically turned off when not in use, optimizing energy consumption according to production needs.

Example: production equipment warms up for 2 hours - if automatically started according to the production schedule, operator time is saved.

Machine vision systems monitor production lines, detecting product defects and ensuring consistent quality.

Monitoring employee movement near production lines to automatically stop equipment if safety risks are detected.

Factory layout simulation allows virtually testing different machine layouts and workflows to find the most efficient configuration.

Simulate the production of new products to assess their impact on existing production lines and capacity.

Simulate production processes to assess their efficiency and find opportunities for optimization.

Business and Processes:

Employees May Be Resistant

Technology Suitability

It's important to understand the environment (people, processes, systems)

and do

thorough preparatory work

If you don't adapt business and processes:

If you don't train employees:

If you don't upgrade equipment:

Business continuity is key

Mapping the current situation and creating a prioritized plan

Good preliminary work and thorough planning help avoid unexpected costs and delays.

Mapping the current situation and creating a prioritized plan

Systems:

People:

The primary focus of digitalization is on people and processes. Tools support them.

Usually:

The result:

To ensure success:

In general: factories have been operating for decades, people there are

competent, and improvement projects are already ongoing.

However, there are still ways to be more efficient.

Our solution, Kratt, collects data:

You can see the data in 15 minutes

About the role

You’ll work with data to make manufacturing processes more visible. We combine technical analysis with the industry knowledge of our customers to provide meaningful insights for decision-makers.

We gather real-time production data from devices and people to answer questions like:

Our current core toolstack

What we're looking for

Help factories see, understand, and act on their data.

About the role

You’ll work on our hybrid Edge–Cloud platform and the MES layer built on top of it. Edge systems handle real-time data acquisition, caching, and fallback. The cloud manages storage, processing, and user interfaces. The challenge is to design systems that stay reliable and secure while staying simple to use.

What you'll be working on

Our core toolstack

What we're looking for

Build resilient systems that make the shop floor visible and usable.